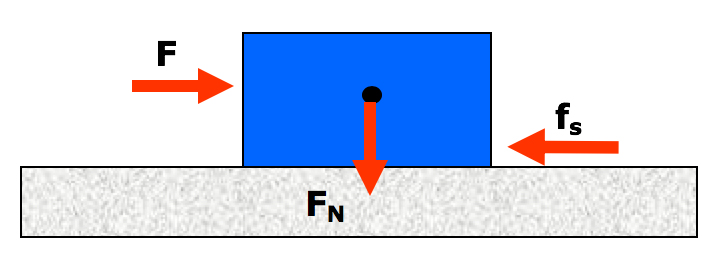

Friction, which is the resistance to relative motion between two bodies, occurs in all sliding and rolling motions. In components that use lubrication to separate rolling or sliding surfaces — such as bearings and gears — there are typically two types of friction: static friction and dynamic friction.

Static friction — also referred to as “stiction” — is the friction that occurs at the beginning of motion, as the bonds between the two surfaces are broken and a lubricating layer begins to build. Dynamic friction occurs once relative motion has begun and a lubricating layer is established. Static and dynamic friction together are sometimes referred to as “Coulomb friction” (after the French engineer and physicist, Charles-Augustin de Coulomb). Once a lubricating layer is sufficiently developed, friction becomes proportional to the relative speed of the surfaces and is termed viscous, or fluid, friction.

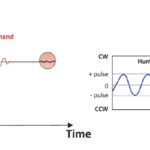

Understanding the types of friction present in motion control components is important because friction poses a special challenge to tuning servo systems. Static friction, which occurs when the system undergoes a zero velocity crossing (when the system begins to move from rest or when a change of direction occurs), is especially problematic because it can cause a system to overshoot its intended position, velocity, or torque and then oscillate as the friction force drops and the system seeks out the set point. And in the worst case, static friction can prevent motion altogether.

In theory, static friction can be compensated by increasing the gains in the servo control loop — particularly proportional and/or integral gain. However, this would require excessively high gains and cause instability once motion commenced and the friction transitioned from static to dynamic.

To address the problems caused by friction, servo controllers often include friction compensation functions that produce torque (or force) in the right amount and for the right duration of time to overcome friction forces without causing instability.

Image credit: Schneider Electric

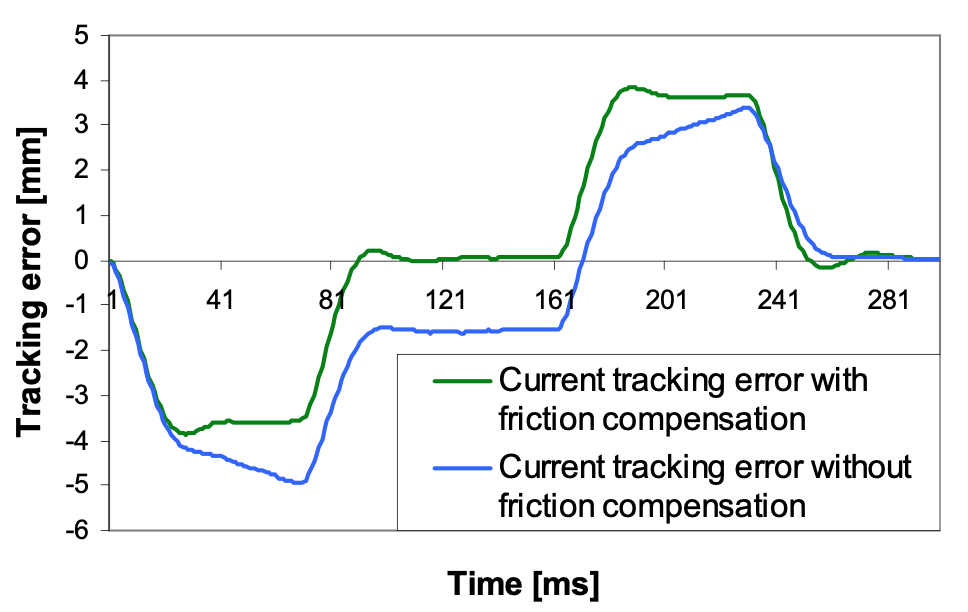

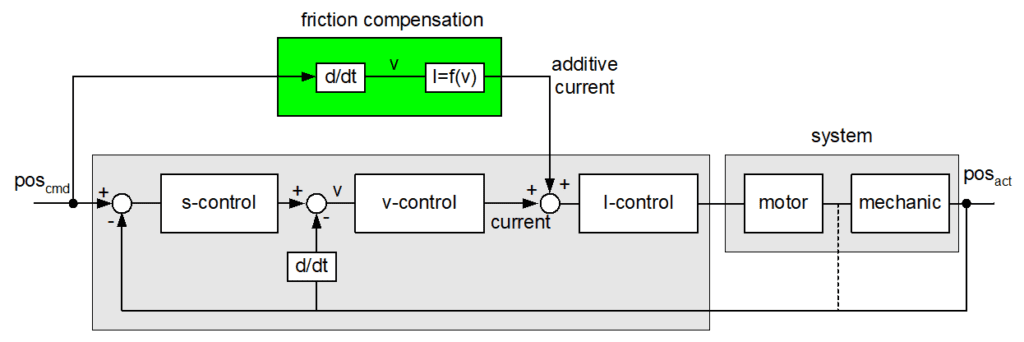

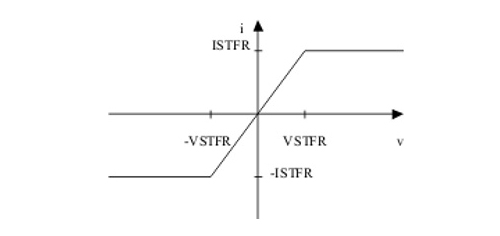

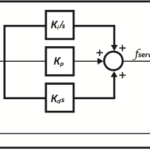

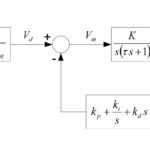

One friction compensation method is a type of feed-forward control. The most common execution of feed-forward to compensation for friction — particularly static friction — is to add a velocity-dependent feed-forward control to the current command. This increases the amount of current sent to the motor, so the motor develops enough torque to overcome the high start-up (static) friction.

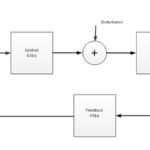

Image credit: Beckhoff

A feed-forward gain is a control action that estimates the ideal output from the control algorithm, predicts the commands needed to achieve zero error, and injects these commands as auxiliary signals into the control loop.

However, because friction forces drop — in many cases significantly — once motion is underway, a “friction compensation window” (a term used by Rockwell Automation) may also be defined. This parameter specifies when and to what degree the friction compensation is applied, based on the either the amount of positioning error or the velocity of the axis. In other words, the friction compensation window ensures that the added torque is sufficient for the type of friction (static or dynamic) the system is encountering at any given point in time.

Image credit: Kollmorgen

Friction compensation is available in most servo controllers and is often implemented in auto-tuning algorithms. While it is useful for almost any system that exhibits high static friction, friction compensation is most commonly used in applications that require very accurate path following, such as coordinated motion and contouring profiles.

Leave a Reply

You must be logged in to post a comment.