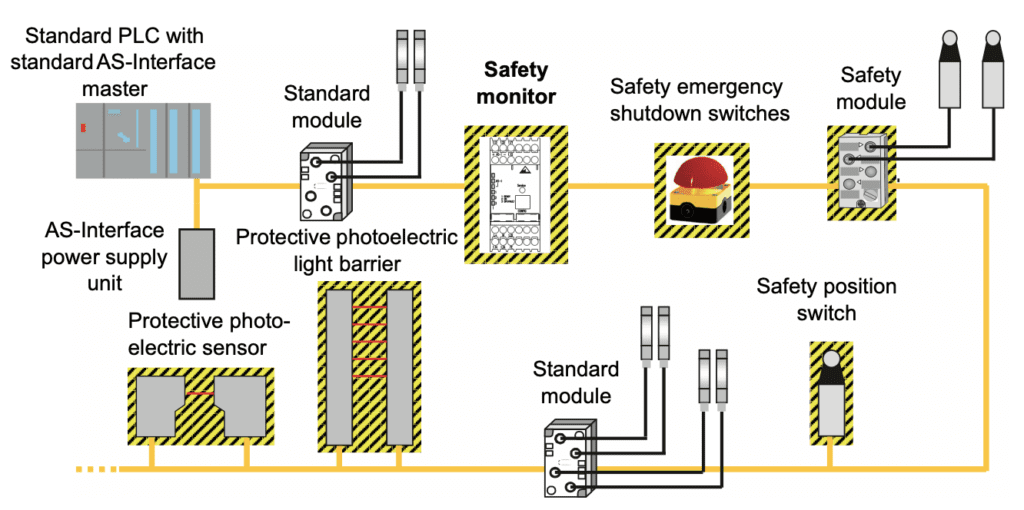

When sensors, actuators, and other lower-level components are used in a functional safety capacity, AS-Interface Safety at Work offers a simple, efficient, bus network for monitoring these safety devices — alongside standard, non-safety devices — on the AS-Interface cable.

Recall that actuator-sensor interface (AS-Interface, or simply AS-I) is a master-slave bus that operates at the lowest level of the fieldbus hierarchy. It replaces parallel wiring for sensors and actuators with a single, 2-wire cable that transmits both data and power. Devices (also referred to as “nodes”) can be added anywhere along the cable and in any topology, such as line, ring, or star.

In some cases, these lower-level devices serve as key parts of a safety function within a machine, and as such, their communication with the master controller also needs to be “safe.”

AS-Interface has addressed the need for safe communication between safety components and higher level controllers with the creation of AS-I Safety at Work — a solution that allows safety devices to be connected on the same AS-I cable and fieldbus as standard (non-safety) devices.

Safety devices that have an AS-I Safety at Work interface can be connected directly to the AS-I cable. Devices that do not have an AS-I Safety interface can be connected via special interfaces, sometimes referred to as “coupling modules” or “adaptation devices.”

Not only does this solution take advantage of the simplicity of AS-I implementation, it also eliminates the cost and complexity of redundant infrastructure. And the safety concept can be easily modified as needs change. Safety devices can be added, moved, or replaced as needed with no restrictions on their implementation and no new wiring required.

Image credit: Siemens

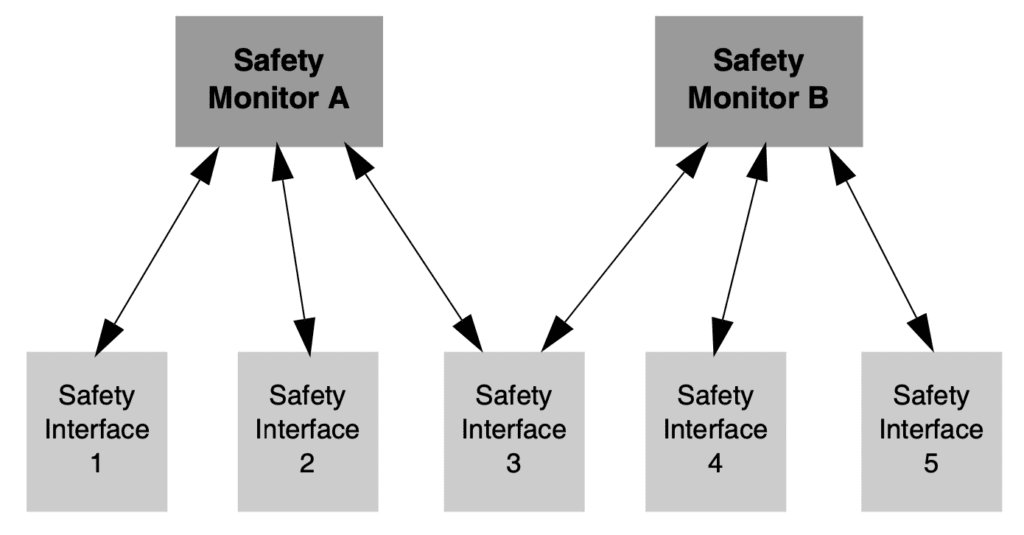

The key to AS-Interface Safety at Work is a safety monitor, which monitors up to 31 safety-related devices — such as e-stops, light curtains, and door latches — on the AS-I bus. Each safety device has a manufacturer-defined code table (a list of 4-bit binary numbers) which is stored by the safety monitor. When the master controller polls a safety device, the safety device transmits its status via a 4-bit code from its code table.

The safety monitor “listens” to this communication and compares the code sent by the safety device to the codes it has stored for that device. If the code is not listed in that device’s code table, or if there is a problem with network communication (such as an interruption or missing or delayed response from the device) the safety monitor switches off the relevant safety outputs, with a maximum reaction time of 40 ms.

Image credit: Schneider

AS-I Safety at Work has been certified to meet functional safety standards PLe/Category 4 according to EN/ISO 13849-1 and SIL 3 according to EN/IEC 62061.

Leave a Reply

You must be logged in to post a comment.