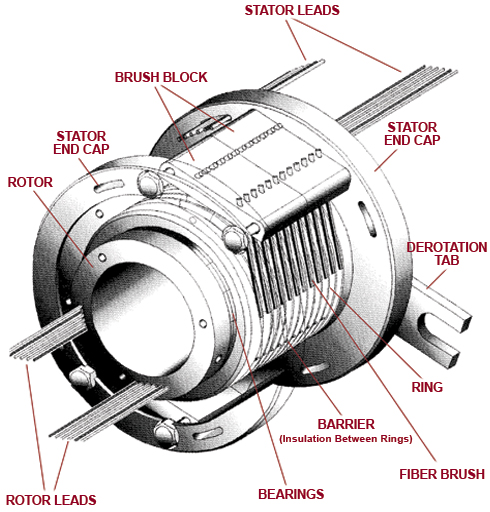

Slip rings — also referred to as rotary electrical joints, electric swivels, and collector rings — are devices that can transmit power, electrical signals, or data between a stationary component and a rotating component. The design of a slip ring will depend on its application — transmitting data, for example, requires a slip ring with higher bandwidth and better EMI (electromagnetic interference) mitigation than one that transmits power — but the basic components are a rotating ring and stationary brushes.

Image credit: Moog Inc.

If the rotation of one component involves a fixed number of revolutions, it may be possible to use spools with sufficient cable length and rotating speed to allow for the required revolutions, although cable management in this setup can be quite complex. But if one component rotates continuously, using cables to transmit signals between the rotating and stationary components isn’t practical or reliable in many cases.

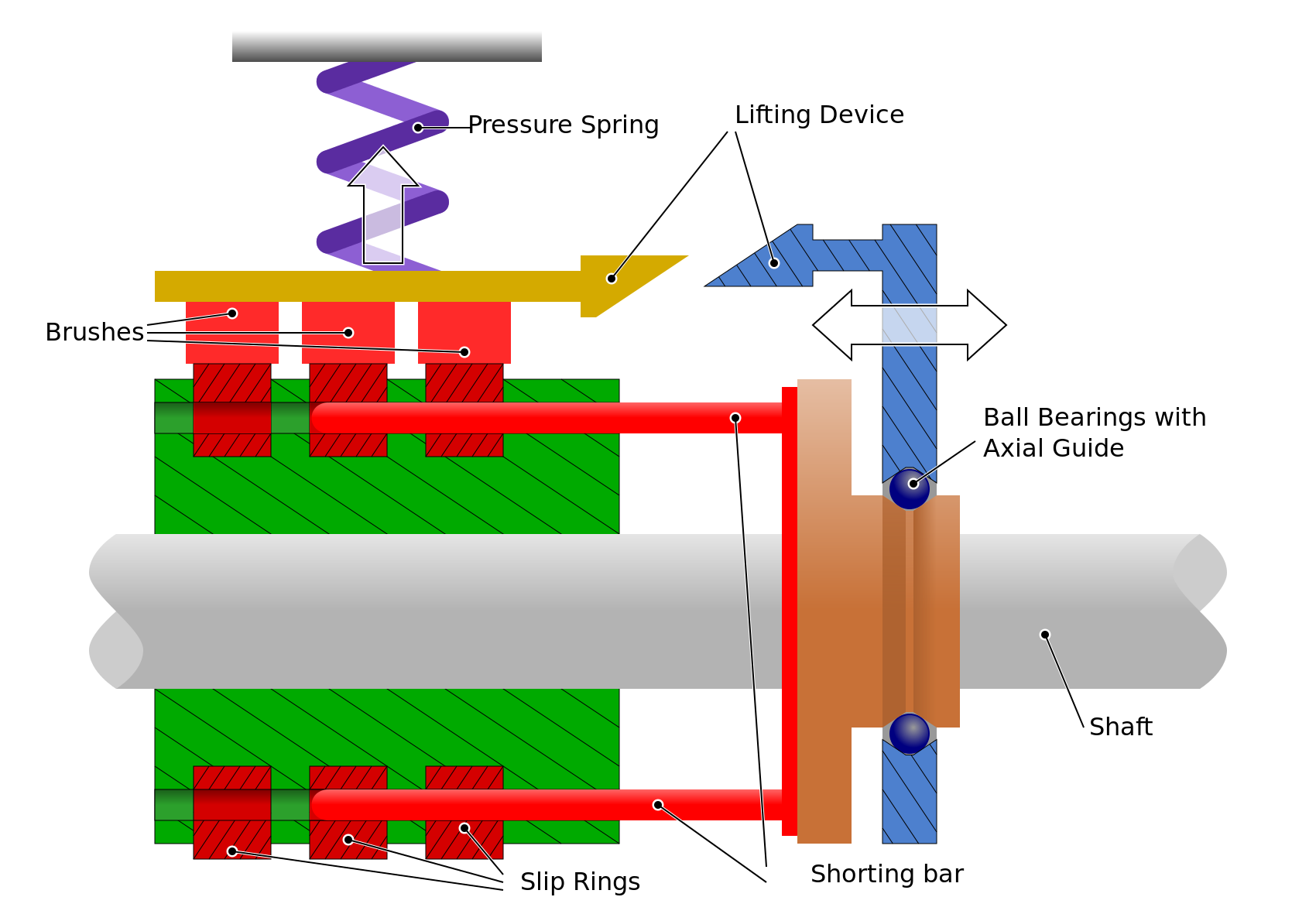

Slip rings in AC motors

In a version of the AC induction motor referred to as a wound rotor motor, slip rings are used not for transferring power, but for inserting resistance into the rotor windings. A wound rotor motor uses three slip rings — typically made of copper or a copper alloy — mounted to (but insulated from) the motor shaft. Each slip ring is connected to one of the three phases of rotor windings. The slip ring brushes, made of graphite, are connected to a resistive device, such as a rheostat. As the slip rings turn with the rotor, the brushes maintain constant contact with the rings and transfer the resistance to the rotor windings.

Image credit: Wikipedia

Adding resistance to the rotor windings brings the rotor current more in-phase with the stator current. (Recall that wound rotor motors are a type of asynchronous motor, in which the rotor and stator electrical fields rotate at different speeds) The result is higher torque production with relatively low current. The slip rings are only used at start-up, however, due to their lower efficiency and drop-off of torque at full running speed. As the motor reaches its operating speed, the slip rings are shorted out and the brushes lose contact, so the motor then acts like a standard AC induction (aka “squirrel cage”) motor.

Slip ring or commutator?

You may have noticed that the design and function of a slip ring sounds very similar to that of a commutator. While there are similarities between the two, there are critical distinctions between slip rings and commutators. Physically, a slip ring is a continuous ring, whereas a commutator is segmented. Functionally, slip rings provide a continuous transfer of power, signals, or data. Specifically, in AC motors, they transfer resistance to the rotor windings.

Commutators, on the other hand, are used in DC motors to reverse the polarity of current in the armature windings. The ends of each armature coil are connected to commutator bars located 180 degrees apart. As the armature spins, brushes supply current to opposing segments of the commutator and, therefore, to opposing armature coils.

Slip rings are used in virtually any application that includes a rotating base or platform, from industrial equipment such as index tables, winders, and automated welders, to wind turbines, medical imaging machines (CT, MRI), and even amusement park rides that have a turntable-style operation. Although the traditional application for slip rings was to transmit power, they can also transmit analog and digital signals from devices such as temperature sensors or strain gauges, and even data via Ethernet or other bus networks.

Feature image credit: Rotary Systems Inc.

Leave a Reply

You must be logged in to post a comment.