Rotating components are common in motion applications — robot arms, winders, spools, spindles, and rotary tables are just a few examples. And while creating rotary motion is easy, when air or liquids need to be transferred from a stationary supply to a rotating component for cooling, heating, lubricating, or transmitting fluid power, the task becomes more complicated. This is where rotary unions come in.

Rotary unions provide an interface that allows fluid media — air, steam, or liquid — to be transferred between a rotating component and a static component. They’re designed to accommodate a wide variety of media conditions, including very high and low temperatures, flows, and pressures, including vacuum applications. And unlike other fluid transfer mechanisms, rotary unions work for applications involving any combination of rotation angles, including continuous rotation in one direction.

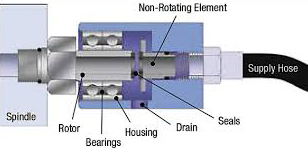

Image credit: Dublin Company

Rotary unions are referred to by a variety of names, including rotating unions, rotary joints, rotary swivels, and rotary couplings.

There are numerous designs and configurations for rotary unions — in fact, they’re often custom-designed for the application — but all rotary unions are made up of four basic parts: the housing, one or more bearings, the shaft, and one or more seals.

The housing is typically the stationary part and is connected to the media supply. The shaft is independent of the housing and rotates with the connected rotary equipment. Media can flow through the union radially or axially via ports in the housing. The rotating part is supported by radial bearings — typically one or more fully sealed deep groove ball bearings.

The most important component of the rotary union is arguably the sealing mechanism, which prevents or reduces leakage between the rotating and stationary components, and must do so with minimal friction and wear. Seal types range from simple lip seals to more complex spring-loaded mechanical seals that automatically adjust to minimize the pressure on the seal faces, reducing friction and wear.

Of course, the fluid transfer should ideally be leak-free, but in some applications, completely leak-free transfer is not possible. For these cases, the media is prevented from being released into the environment by a collection system that recovers the leaked media, protecting surrounding equipment and personnel.

This video from Dynamic Sealing Technologies Inc. demonstrates how rotary unions transfer fluid between rotating and stationary component, with examples of their use in various industries.

Whether choosing a standard, off-the-shelf rotary union or designing a custom product, the following factors should be considered:

- type of media being transferred

- speed of rotation

- flow rate of media

- pressure of media

- temperature of media

- allowable leakage

The type of media is especially important, since the housing, shaft, and seal materials must be compatible with the fluid flowing through the union. Fluid media can range from water to highly corrosive liquids and steam, and manufacturers address the challenges of each by offering a wide range of materials, not only for the housing and shaft, but also for the seals.

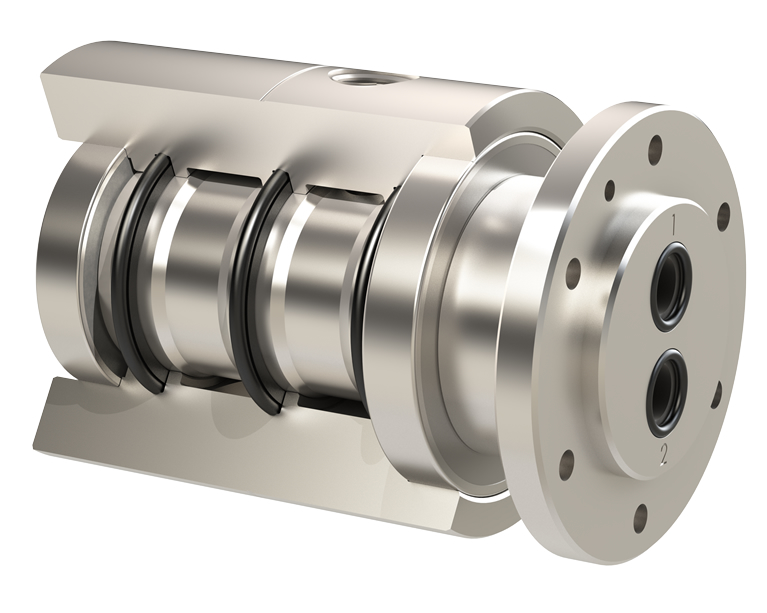

Although single- and dual-flow designs are most common, rotary unions can include multiple independent flow paths that allow different media to be transferred concurrently without mixing. It’s also common for slip rings or fiber optic rotary joints to be integrated with rotary unions, allowing the passage of both fluids and electrical or fiber optic cables.

Image credit: Kadant Inc.

In motion control systems, rotary unions can be found in robot joints, especially for transferring air or fluid to end-of-arm tooling. They’re also used for passing vacuum or air pressure through rotary air bearing stages, and for supplying coolant and lubrication to machine tool spindles.

Feature image credit: Moog

Leave a Reply

You must be logged in to post a comment.