Updated January 2020 ⚙️ Power-transmission devices are increasingly customized, and gearsets and gearmotors are no exception.

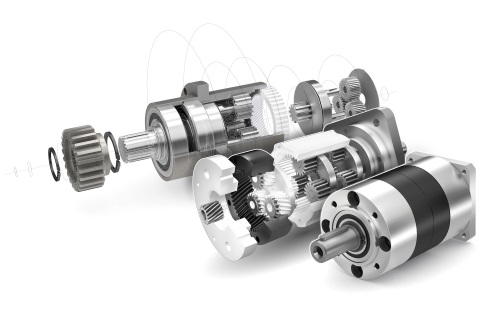

However, today’s custom and standard gear products aren’t mutually exclusive, according to Heinz Gert Hagedorn, who leads sales and development for planetary transmissions at IMS Gear. His company makes modular planetary transmissions and other modular drives based on parts that form some 10,000 configurations of low-noise planetary transmissions in plastic, plastic-metal and metal—and myriad variable reduction ratios, engine pinions, flanges, outputs, bearings and grease grades for a range of applications.

“Applications must satisfy highly divergent parameters, and modular systems for planetary drives replicate the performance of custom without the development and investment costs, not to mention long production lead times and time to market,” said Hagedorn.

Low-volume custom gearing

But there’s another trend in procuring custom gearboxes, according to Craig Van den Avont, president of GAM Gear—particularly for smaller volumes. His company offers myriad standard gearboxes, but flexible in-house manufacturing lets it tailor gearboxes and components to applications.

“More automation, machine-tool flexibility and software capability have spurred quite a bit of reshoring, bringing manufacturing back to the U.S., particularly for low-and-medium-volume orders. That’s how we work more closely with designers in the U.S., both for new designs and servicing gearboxes in existing machines,” said Van den Avont in a recent interview.

Others agree. “In terms of manufacturing, we’ve begun making more products domestically as we realize the importance of being close and quickly supplying gearing to North American customers,” said Robert Mullins, V.P. of sales at Harmonic Drive.

That emphasizes technical service and support with accessible and responsive application engineers and offices, according Mullins. His company has also expanded a line of servomotor-driven electric actuators with myriad options for input voltage, encoders, drives and cabling. Engineers can load drives with the actuator’s motor parameters to simplify implementation onsite.

… or modular gear designs to get custom setups

A common view is that bespoke gear designs don’t make sense unless they’re made in high volumes (to justify the cost). Hagedorn stressed that modular designs are an option here, to get the benefits of standardization—namely, verified technologies and a good price-performance ratio. “Even the entry-level version of our modular gearing offers more than 1,300 possible variants,” said Hagedorn. “These come straight from the warehouse to give engineers quick delivery of small to medium quantities.” That’s also true of gearsets for sample testing, from the initial concept to functioning samples to production parts.

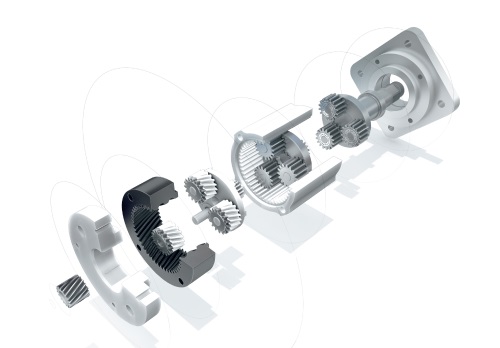

Case in point: About five years ago, IMS began making tailgate drives for offroad vehicles and pickup trucks. The customer wanted an electric actuator to automate tailgates. So, IMS studied their CAD designs and provided catalog versions of standard transmissions with steel gears and suitably configured ball bearings. Next came functional tests. A later version was too noisy, so IMS made a low-noise iteration.

Now, in production versions of the drive, the helical ring gear of the first transmission stage is steel, and the ring gear for the second transmission stage, as well as all planet gears for both transmission stages, are plastic. “Even when the reduction ratio needed altering just before the start of full production, we found a quick solution,” said Hagedorn. Such a change with traditional manufacturing would’ve delayed production for months. Today, there are more than 30 derivatives of the tailgate drive in volume production. Each iteration accounts for the application’s reduction ratios, load-bearing requirements, restrictions on installation space during the orientation phase, and overall quantities.

In contrast, GAM Gear emphasizes service even for small quantities of custom gearboxes: “The service side is better … and 3D modeling software is better than ever, as is CAM software, so we can now take 3D models down into the machine tool in post-processing work that’s simpler than it was in the past. That enables more customization than ever,” said Van den Avont. Plus high-precision gearboxes today are less costly to manufacture than before. That’s thanks to more automation of machine tools as well as expanded machine-tool capabilities in the form of live tooling and multi-axis machines. “In fact, today’s machine tools are much simpler to program than those of the past. So, we can quickly program machines to output small quantities of unique components for custom gearboxes,” added Van den Avont.

In fact, Van den Avont predicts that smart components will proliferate as the cost of monitoring components comes down. “We’ll have sensors inside gearboxes that will tell plant-maintenance personnel when a gearbox is threatening to fail. Such sensors can already detect increased bearing vibration, decreased output torque, and increased gearbox temperature,” he said. When it becomes economically viable to add such feedback to even simple systems, the industry will get the power to change out gearing subcomponents before catastrophic failure occurs. That’s particularly helpful with gearboxes, because after a gearbox bearing fails, the whole assembly is scrap.

How much would price need to drop before this is viable? “I don’t have an exact number but it’s currently too expensive to add sensors to most gearboxes,” said Van den Avont. “Generally, we consider new technology features viable when they add no more than 10% or 15% to the cost of a gear product.”

“Beyond that, we see improved materials and higher-performing gearboxes thanks to gear-cutting machines outputting better quality than ever, even while reducing cost,” he added. Others agree.

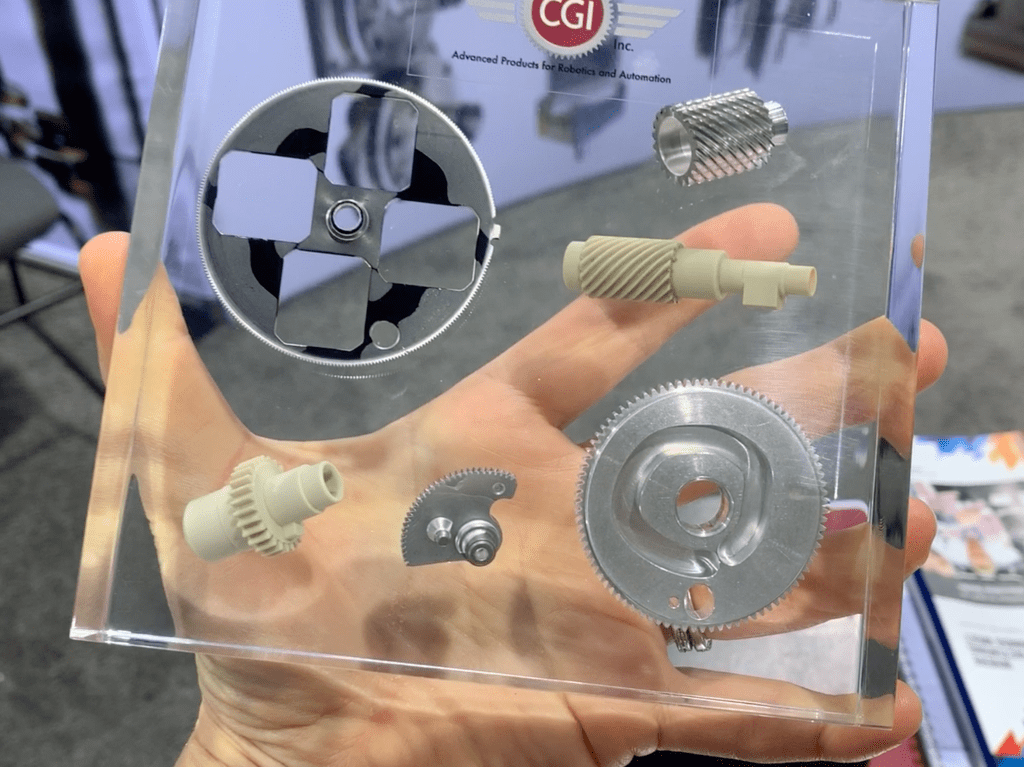

“Now we can optimize gear-tooth forms for noise reduction, high strength, improved life and more,” said Brien Shirey, V.P. of engineering at CGI Inc.

Plus new specialty materials, coatings, and bearings are boosting gear performance in smaller packages, Shirey added.

The trend toward lighter, smaller gearing is perhaps most apparent in positioning machines. Consider harmonic gearing, which often drives motion-control applications where low weight and size and high output rotary positioning accuracy are paramount. “Over the last few years, we’ve made lighter-weight gearing to enhance the ratios of output torque to weight as well as output torque to size,” said Mullins. The drives are more compact than those of 10 years ago, which saves OEMs from the pain of engineering special space-saving actuators.

Industries spurring changes in gear design include aerospace, medical, military, alternative energy, semiconductors and packaging. “Designs are becoming more complex, requiring customization and creative thinking,” said Shirey. Gear manufacturing and distribution are also constantly changing, thanks to overseas competition and demand for optimization. “That impacts product design because engineers need more complex gear products with lower costs and diminished lead times, if not immediately available inventory, said Shirey.

Leave a Reply

You must be logged in to post a comment.