Processing fresh fish necessitates a hygienic environment with regular washdowns, followed by frigid temperatures for freezing final products. That’s why machinery in such settings must be extremely rugged — and why one fish supplier has used motors from Bauer Gear Motor for the last few years.

Van Der Lee Seafish processes approximately 200 tons of fresh fish every week. Fish is subject to conveyor-driven sorting, filleting, breading, freezing, and packaging processes. Drives for these conveyors must meet strict food-industry hygiene requirements.

“Product quality is paramount, so fish must be processed quickly and efficiently,” said technical director Willem Van der Lee. “We can have seven processing and five packaging lines operating at any given time, and each one employs many motors and drives. That necessitates spare parts be kept to minimize downtime should a breakdown occur.”

That’s why Van Der Lee Seafish standardized on Bauer’s gearmotors throughout its food-processing facility a few years ago. The AsepticDrive from Bauer Gear Motor (of Altra Industrial Motion Corp.) has a hygienic gearmotor design with smooth surfaces and no cooling fins that can promote bacteria accumulation. Standardizing on the gearmotor minimized spare-parts inventory. What’s more, the permanent magnet synchronous motors (PMSMs) have high energy efficiency, especially under partial load. Plus the synchronous nature of the PMSM motors maintains constant speed independent of load. That means as long as the mains frequency is held constant the motor speed doesn’t vary, even under overloading or voltage drops.

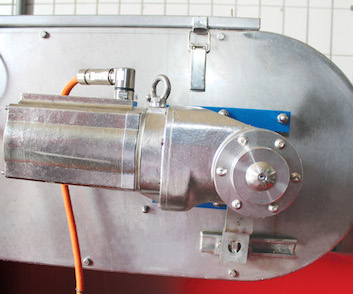

The gearmotors delivered the promised level of performance on almost all counts. One exception was on some motors subject to mechanical damage from other equipment. On these units, degradation of the hygienic coating threatened to compromise the hygienic design. So for certain locations in the plant, Bauer engineers supplied a newer gearmotor — a stainless-steel HiflexDrive variation with maximum mechanical resilience and the ability to withstand harsh washdowns.

“The AsepticDrive has let us trim spare-parts inventory, and the HiflexDrive in stainless steel is a direct replacement for running in frozen storage areas,” added Van der Lee.

Bauer’s HiflexDrive comes in a modular design allowing gearbox, electric motor, and external finish selection. Motors rated up to IE5, according to IEC TS 60034-30-2, offer top energy efficiency, while pairing with variable speed drives allows exact conveyor-speed setting. Including a PMSM in the drives reduces heat losses from the rotor by 100% and total losses by approximately 25% — plus boosts total efficiency by 10% or more. Such savings are significant especially for stainless-steel motor variations that dissipate heat less efficiently than those built with aluminum or cast-iron housings.

HiflexDrive system flexibility lends itself to the food and beverage industry. The stainless-steel construction eliminates hygiene risks posed by mechanical impacts or extended operation subject to rigorous cleaning. Ingress protection is to IP69K — a washdown designation for applications subject to high temperature and high-pressure water.

Flexible designs also mean Van der Lee Seafish can move its conveyors around to various areas and not worry about drive reliability. Stainless-steel HiflexDrive units ensure maximum productivity.

Leave a Reply

You must be logged in to post a comment.