All electric motors operate with inherent losses from a number of different areas. Some are inherently mechanical (think friction losses as heat) while others are electrical, from current in conductors, also known as I2R losses, to losses due to hysteresis and eddy currents in the iron components of a motor.

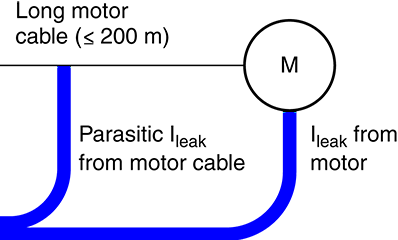

One type of loss that is especially pernicious is leakage current from the motor to ground. The fact is that some small amount of current can flow from the motor to ground in all electrical equipment, usually as a result of some type of fault in the equipment or cabling. The amount for the most part is small, perhaps on the order of milliamps, but it is present nonetheless and poses a safety risk to human operators.

Leakage currents can flow through the insulation surrounding conductors. Electrically speaking, insulators have both resistance and capacitance, and leakage current can flow through both. Old or damaged insulation means a lower resistance and hence more potential current flow. Also, the longer the conductor the more capacitance, and therefore more leakage current flow. Typical allowable leakage currents in IT and medical equipment, for instance, are in the range of a milliamp or two to sub-milliamps.

So what is likely to cause leakage currents? For one, unshielded cables. Also, any other sources of electrical noise that can couple to the motor or motor cabling. Remember, leakage current can be an indicator of trouble in conductors and insulators. A common way to check for leakage current is to use a clamp-type current meter that fits around a conductor and gives a read-out of the current. The best ways to prevent leakage current are to always use shielded cables on motor installations and to make sure that these cables are grounded at both ends. Also, check cables and insulation for damage and replace ones that are broken or damaged.

Leave a Reply

You must be logged in to post a comment.