KHK USA Inc. has launched an extensive line of metric spur gears. A large selection of off-the-shelf KHK spur gears are available in many materials, configurations, modules and numbers of teeth, and KHK quick customized products can be ready within 5 business days.

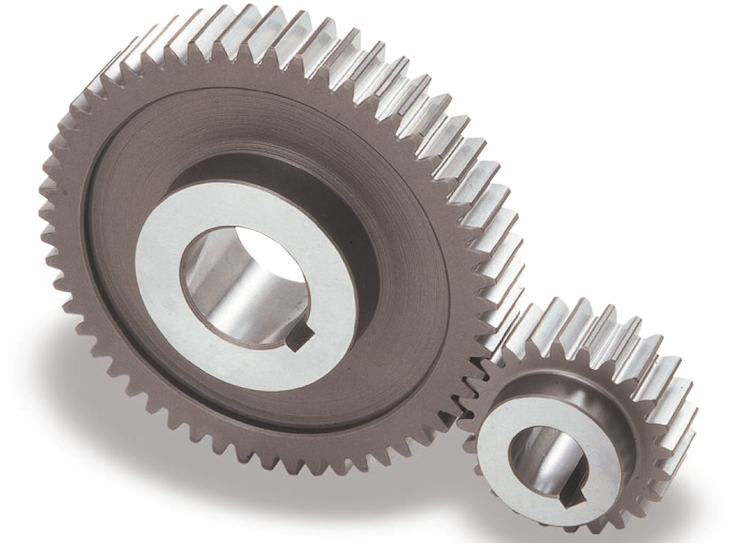

Spur gears are cylindrical disks that have involute shaped teeth cut into their face. The meshing of spur gears results in rolling contacts producing high efficiency of about 95 to 98%. Secondary operations that can be performed include opening the bore, adding of keyways, adding of tapped holes, or reduction of the hub diameter.

KHK spur gears are available in a wide variety of materials including structural carbon steel S45C, structural alloy steels SCM440 (medium carbon steel) and SCM415 (low carbon steel), gray cast iron FC200, stainless steels SUS303 and SUS304, nonferrous metal C3604 (free cutting brass), engineering plastics MC901 and MC602ST. Materials conform to U.S. standards including AISI, SAE, ASTM, and AGMA.

The production process of KHK cylindrical gears, including spur gears, depends on consideration of tooth size expressed in module or DP (diametral pitch), configuration, material, heat treating, method for finishing the tooth surface, precision of the gears and manufacturing quantity. The typical production sequence involves cutting off material, blank making on a lathe, tooth cutting on a hobbing machine and deburring. KHK also offers a new method in which a 5-axis machining center is used in combination with gear manufacturing software.

For more information, visit: www.khkgears.us/products/spur-gears.

Leave a Reply

You must be logged in to post a comment.