Friction, which is the resistance to relative motion between two bodies, occurs in all sliding and rolling motions. In components that use lubrication to separate rolling or sliding surfaces — such as bearings and gears — there are typically two types of friction: static friction and dynamic friction. Static friction — also referred to as “stiction” […]

FAQs + basics

What is dual-loop control for servo systems and when is it used?

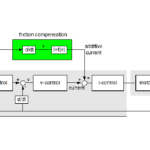

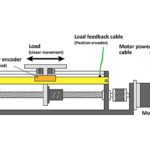

In servo-driven systems, feedback for position, velocity, and/or torque control is typically provided by a rotary encoder or resolver mounted to the motor. But mechanical components and connections in the drivetrain — such as gearboxes, ball screws, and couplings — are not perfectly rigid and introduce backlash, compliance, and windup into the system. This lack […]

What are rotary actuators and how do they differ from other rotary tables?

When we think about actuators, we typically think about linear actuators — devices that move loads in a straight line, driven by a screw, belt, or other mechanical power transmission device. But there also exists a class of actuators that provide rotary motion for positioning a load radially around a fixed axis. While these rotary […]

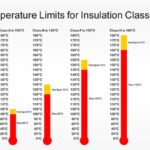

What does motor insulation class specify and why is it important?

Any time current flows through a wire — such as the windings in a motor — resistance in the wire, as well as other losses, cause heat to be generated. This heat will eventually transfer to other parts of the motor, causing them to degrade over time. One of the key components affected by this […]

Motion Control Tips: The top 5 posts for 2020

An end-of-year tradition here at motioncontroltips.com is to look back at some of our most viewed articles we published on the site throughout the year. This represents what you, our readers, clicked on the most throughout the year. Curiously enough, some of the most-read content in 2020 revolved around electrical and networking topics. We’re not […]

What is inrush current in an AC motor and why does it matter?

When an electrical device, such as an AC induction motor, is switched on, it experiences a very high, momentary surge of current, referred to as inrush current. When an AC induction motor is started, the supplied voltage creates a magnetic field in the stator, which induces a magnetic field in the rotor. The interaction of […]

What is a motor control center (MCC)?

Manufacturing plants often contain dozen, if not hundreds, of motors — driving everything from packaging and processing equipment to fans and pumps. Motor control centers allow facilities such as these to centralize control of some or all of their motors into one location. The basic structure of a motor control center (MCC) is a metal cabinet […]

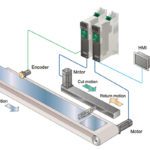

What is a flying shear application in motion control?

The term “motion control” spans a wide range of applications that involve controlling the movement of a linear or rotary axis to achieve a goal such as moving to a specified position or precisely following a defined path. And although there are numerous variations, at their core, many of these applications can be grouped into […]

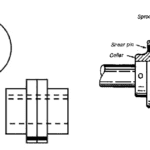

How do shear pin torque limiters work and when are they used?

Shear pin torque limiters are a simple, cost-effective design for protecting equipment from torque overloads. In their most basic form, they incorporate a pin (or, for very high torque ratings, multiple pins) inserted between two rotating elements, such as discs or flanges. When torque is being transmitted from the driving to the driven load, the […]

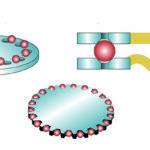

How do ball detent torque limiters work and when are they used?

Rotating equipment such as motors, gearboxes, and fans can experience a torque overload if the system encounters an unexpected malfunction such as a jam or crash of the driven load. One way to protect these expensive components — and to avoid physical injury to personnel — is to install a torque limiter in the drive […]