Beckhoff will showcase the latest adaptive automation technologies for the intralogistics industry at ProMat 2023. Top highlights in Beckhoff booth S1541 will include the intelligent mechatronic systems, XPlanar and the eXtended Transport System (XTS) now with No Cable Technology (NCT), and the TwinCAT/BSD alternative operating system (OS) for Beckhoff controls. An advance preview of the MX-System, the emerging hardware platform for completely cabinet-free machine design, will also be on display at the show from March 20-23 at the McCormick Place convention center in Chicago.

Through a variety of hands-on demos, visitors to the Beckhoff booth will be able to interact with the latest in machine control, IoT and analytics, EtherCAT networking, and integrated safety. The fully integrated and flexible automation and IoT portfolio from Beckhoff helps engineers tackle wide-ranging intralogistics applications to build the data-driven warehouses of tomorrow – today.

Intelligent transport systems enable adaptive automation

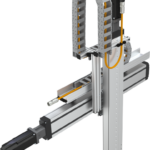

Proven in thousands of applications globally, XTS is helping equipment manufacturers completely rethink how to solve complex material handling challenges. XTS delivers high dynamics, software-based changeovers, and dramatic footprint reductions. In its ProMat debut, the new NCT extension provides contactless, continuous power supply and synchronous real-time data transmission to XTS movers. The system can now incorporate wide-ranging end effectors and powered devices for processing, material handling, or inspection tasks directly on the wireless mover during operation. NCT preserves the compact design of XTS, leverages ultra-fast EtherCAT communication, and is fully integrated into TwinCAT 3 automation software.

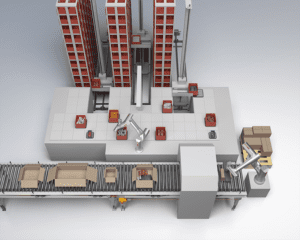

The XPlanar “flying motion” system delivers unbeatable competitive advantages with magnetically levitating movers. Taking an adaptive automation approach, XPlanar can fundamentally change how equipment manufacturers approach material handling and robotic tasks to disrupt their industry segments. Boosting throughput and flexibility, the system boasts zero friction, automatic collision avoidance, path planning, anti-slosh, 360° rotation, and zero wear on the system, among other benefits. The base tiles can also be covered with stainless steel, glass, or plastic for hygienic distribution and fulfillment environments, such as meal kits, health product subscriptions, or pharmaceuticals as just some examples.

PC-based control advantages, now without Windows

The TwinCAT/BSD OS continues to see great success in intralogistics applications. Not only does TwinCAT/BSD provide an alternative to Windows, but it also offers the security of a modern UNIX-like OS, a selection from a wide range of powerful CPUs, and all of the advantages of Beckhoff machine control technologies. The solution works seamlessly on Beckhoff controllers as a non-Windows OS in conjunction with the universal engineering environment and deterministic runtime of TwinCAT.

Continuing the existing benefits of the Beckhoff control architecture, the TwinCAT/BSD environment supports the execution of third-party software from the large FreeBSD repository. The new Hypervisor extends this capability further by enabling virtual machines to run third-party software in Linux, Windows or other OS environments on the same controller. Also continuing the existing benefits of the TwinCAT automation platform, separate tasks can be executed in separate cores of a multi-core processor.

The future of intralogistics is cabinetless with MX-System

In another ProMat first, Beckhoff will highlight an emerging technology for comprehensive, IP67-rated machine control: MX-System. Every square foot is valuable in a distribution operation, yet electrical cabinets devour limited floor space, increase installation efforts, add costs, and eliminate system flexibility. Freeing up this wasted space has long been a priority for Beckhoff, with innovations like EtherCAT P, the AMP8000 distributed servo system, and the C7015 ultra-compact Industrial PC (IPC), an IP65/67 machine controller. Now MX-System puts a truly cabinet-free solution for complete machine control and system engineering into view. The ProMat sneak peek will highlight how the MX-System will handle all tasks and requirements of a machine’s control cabinet in a space-saving design.

Automation solutions for the smart warehouse of tomorrow

Visitors to the Beckhoff booth can explore the deep, feature-rich New Automation Technology portfolio. From servo solutions of all sizes to MDR controllers to wide-ranging EtherCAT I/O and inherently scalable machine control hardware, Beckhoff delivers a fully integrated, flexible automation platform to optimize intralogistics equipment and operations.

“The intralogistics industry keeps hearing about building data-driven smart warehouses, and at ProMat 2023, Beckhoff will show how it’s possible today,” said Doug Schuchart, Global Material Handling & Intralogistics manager at Beckhoff Automation. “While some in the industry are looking ahead to tomorrow, others are still trying to catch up with demand from the e-commerce boom in recent years. Our flexible, scalable automation portfolio offers solutions for many different scenarios – from greater data throughput and freedom of topology with EtherCAT to IoT and advanced control in TwinCAT all the way to next-level mechatronics like XTS and XPlanar. We look forward to showing how these technologies can deliver exciting competitive advantages for today’s leaders in distribution and fulfillment.”

Leave a Reply

You must be logged in to post a comment.